1.Quick Details

Type:Electrode Paste

Application:steel making/EAF smelting/LF refining

Length:1400-2600mm

Grade:RP (Regular Power)

Resistance (μΩ.m):5.5-8.0

Apparent Density (g/cm3):1.60-1.75

Thermal Expansion:2.7-2.8

Flexural Strength (N/m2):7.0-16.0

ELASTIC MODULUS:8.0-12.0Gpa

ASH:0.2-0.3% Max

Raw Material:100% Neddle Needle Coke

Nipple:3TPI 4TPI

Style:RP Regular Power Graphite Electrodes

Current Load:1000a-42000a

current density:9-31

Color:Grey Black

2.Supply Ability

3000 Ton/Tons per Month

3.Packing & Delivery

STANDARD PACKAGE IN PALLET.SPECIAL PACKAGE AVAILBLE

4.Product description

Grade: RP/HP/UHP

Diameter: 300/350/400/450/500/550/600/700/800mm

Length: 1500-2700mm

Nipple: 3TPI,4TPI

We can manafacture and export graphite electrodes in different grade , shape and dimension. Whenever you need it , please feel free to let us know. We promise you the top quality and lower price.

Parameter of graphite electrode:

| Nominal Diameter (mm) | Regular Power | High Power | Ulra High Power | |||

| Current Load(A) | Current Density(A/cm2) | Current Load(A) | Current Density(A/cm2) | Current Load(A) | Current Density(A/cm2) | |

| 200 | 5000-6900 | 15-21 | 5500-9000 | 18-25 | ---- | ---- |

| 225 | 6100-8600 | 15-21 | 6500-10000 | 18-25 | ---- | ---- |

| 250 | 7000~10000 | 14-20 | 8000~13000 | 18-25 | ---- | ---- |

| 300 | 10000~13000 | 14-18 | 13000~17400 | 17-24 | 15000~22000 | 20-30 |

| 350 | 13500~18000 | 14-18 | 17400~24000 | 17-24 | 20000~30000 | 20-30 |

| 400 | 18000~23500 | 14-18 | 21000~31000 | 16-24 | 25000~40000 | 19-30 |

| 450 | 22000~27000 | 13-17 | 25000~40000 | 15-24 | 32000~45000 | 19-27 |

| 500 | 25000~32000 | 13-16 | 30000~48000 | 15-24 | 38000~55000 | 18-27 |

| 550 | 32000~40000 | 13-16 | 37000~57000 | 15-23 | 42000~66000 | 17-26 |

| 600 | 38000~47000 | 13-16 | 44000~67000 | 15-23 | 49000~88000 | 17-26 |

| 700 | 48000~59000 | 12-15 | 59620~83600 | 13-18 | 70000-110000 | 17-24 |

Product Features:

Low resistivity

Low ash

Good electrical conductivity

Good oxidation resistance

Strong thermal shock resistance

High mechanical strength

Compact and uniform structure

Product Details:

UHP | ||||||

Item | Classification | Unit | Nominal Diameter (mm) | |||

300-400 | 450-500 | 550-600 | 700 | |||

Electrical resistivity max | Pole | μΩm | 5.5 | 5.5 | 5.5 | 5.5 |

Bending strength min | Pole | Mpa | 10.5 | 10.5 | 11.0 | 11.0 |

Young's modulus max | Pole | Gpa | 14.0 | 14.0 | 14.0 | 14.0 |

Bulk density min | Pole | g/cm3 | 1.68 | 1.68 | 1.68 | 1.68 |

Thermal expansion coefficient max | Pole | ×10-6/ºC | 1.5 | 1.5 | 1.4 | 1.4 |

Ash Content max |

| % | 0.2 | 0.2 | 0.2 |

|

More Products:

1.The electrode holder should be held in the place beyond the security line of the top electrode;otherwise, the electrode would be easily broken.the contact surface between the holder and the electrode should be cleaned up regularly to maintain a good contacting,the cooling jacket of the holder shall be avoided from water leakage.

2.Identify the reasons it there is gap in the electrode junction,do not use them until the gap is eliminated.

3.If there is falling off of nipple bolt when connecting electrodes,it is necessary to complete the nipple bolt.

4.The application of electrode should avoid of tilting operation, particularly , the gr.oup of connected electrodes should not be put horizontally so as to prevent from breaking.

5.When charging materials to the furnace,the bulk materials should be charged to the place of the furnace bottom,so as to minimize the impact of the large furnace materials on the electrodes.

6.The large pieces of insulation materials should be avoided of stacking on the bottom of the electrodes when smelting .so as to prevent from affecting the electrode use,or even broken.

7.Avoid of collapsing the furnace lid when rising or dropping the electrodes,which may result in electrode damage.

8.It is necessary to prevent the steel slag from splashing to the threads of the electrodes or nipple stored in the smelting site,which may damage the precision of the threads.

Graphite Electrode Process:

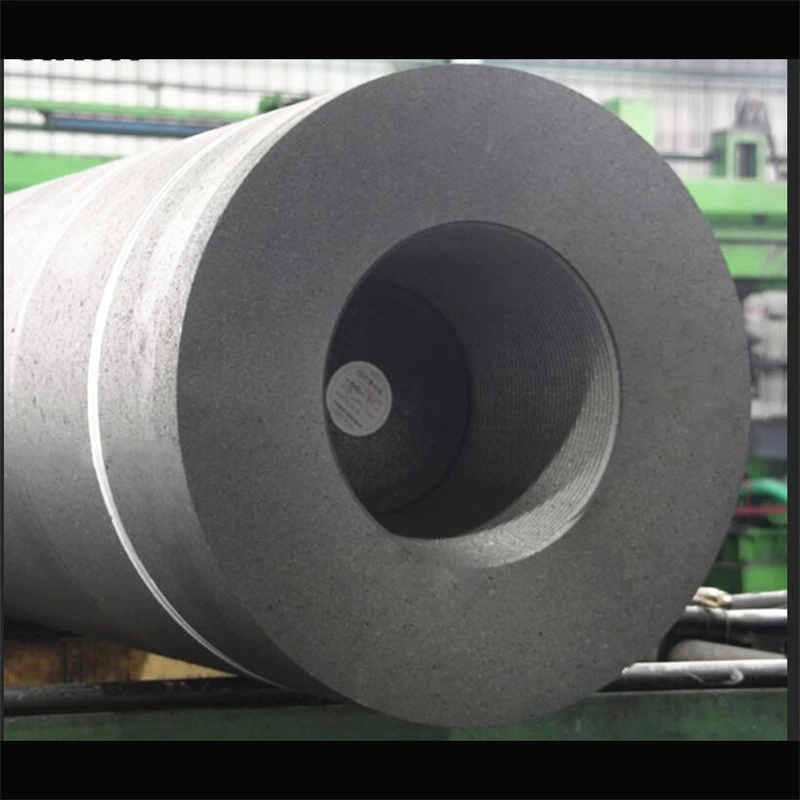

Detailed Images:

The electrodes carry the electricity that heats electric arc furnaces, the vast majority steel furnaces. They are made from petroleum coke after it is mixed with petroleum pitch, extruded and shaped, then baked to sinter it, and then graphitized by heating it above the temperature (3000 °C) that converts carbon to graphite. They can vary in size up to 11 ft. long and 30 in. in diameter.

Usage: An increasing proportion of global steel is made using electric arc furnaces, and the electric arc furnace itself is getting more efficient and making more steel per tonne of electrode.

Advantages of Graphite electrode:

1. Reduce graphite electrodes lateral oxidation rate.

2. Lessen graphite electrodes consumption rate by 15%~20%.

3. Improve graphite electrodes cost efficiency.

4. It is a more cost-effective solution through reducing graphite electrodes purchasing cost by 10%~15%.

5. It is a production efficiency improving solution through reducing risk of graphite electrodes breakage and falling down.

Quality System Control:

- Management delegates and quality inspection department organize internal examine

- every year to supervise and check system running status.

- Second party inspection is carried out by end user.

- Third party inspection is carried out by certificaiton authority

- Packing and logistic is farmed out to other company, and strictly execute as per Contract items.

- We have specific after-sales service to check our product performances

FAQ

1. Are you a trader or manufacturer?

We are manufacturer, we have our own factory.

2. Can you accept OEM or ODM?

Of course, logo is also acceptable.

3. What is the delivery time?

About 10-20 days after signing the contract.

4. What is your payment term?

T/T, L/C, D/P, Paypal, West Union and others.

Service

1. Timely Response: Quick response emails and solutions to your inquiry in 24 hours.

2. Free Sample: Sample and trial orders are accepted for the quality evaluation.

3. Shorter Delivery Time: Book the earliest vessel or plane to guarantee the delivery time.